Fender Villager XII

Grace Da Maren

Fender Villager XII: This Fender Villager was looking good for its age, but, unfortunately, playing worse.

Savvy friends will recognize the background in this photo is not from my new shop, circa 2024. This repair was completed in my basement shop, in early 2023. My dear client asked if I could revisit his guitar in detail as a Featured Repair. While I won't do this for all requests, this job was so very important to him and challenging for me, that it actually makes a great candidate for this section! Here's what he had to say:

"Not that I'm biased of course, but I encourage you to consider writing about how you rebuilt my poor dried-out Fender Villager 12-string."

Here's the list of interventions this guitar received:

Bridge reset

3 cracks repaired

4 cleats installed

11 finish fills with CA glue

Flatten the pickguard (heat between plates of glass)

Heat press the neck

Add washer to trussrod

Glue and clamp bulge at 18th fret (compression heave due to truss rod pressure)

Install neck shim

New parts:

New bridge pins

New strings: .010-.047

I'd never seen this pipe running through a guitar before. Now I know that some folks in industry lovingly refer to it as the 'Fender Chin-Up Bar'! It goes from heel block to tail block, presumably reinforcing the body against the incredible force of those 12 strings. It's a formidable foe against the guitar's desire to fold in half, and an equal adversary for the person who has to install cleats inside the guitar! (Me!)

I don't remember gluing the cracks being a big problem, but I remember looking at the soundboard thinking about all the cracks and finish cracks. As I started sealing the finish around the newly repaired cracks with CA glue, I impulsively decided to start filling the cosmetic finish cracks at the same time. I remember kicking myself - I'd just multiplied the amount of cracks I'd have to level and polish out - I didn't know if I'd be up for the challenge. You can see the numerous cracks I addressed in the photos below. They're all outlined by green tape (designed to keep the CA glue right where I put it). It took longer, but I was really, REALLY pleased with how it turned out. I took years off the guitar.

Sometimes guitar necks have taken all the sass they can from the trussrod, and nothing can be done to straighten out the neck anymore. That's when I employ a trick that works summa the time: the Heat Press. This involves bending the neck (in this case) into a back-bow (an exaggerated bend backward), and heating it up with my incubation lamp. I divide the neck into thirds, and heat it for a couple hours, rotating through the sections. I've made the connection that if the trussrod's function is exhausted, and the neck needs a heat press, the trussrod nut will need a washer. I didn't expect this next wrinkle, though! After I put the guitar back together I was dismayed to find the guitar wasn’t playing well at the 18th fret.

Compression under the fingerboard caused by the truss rod. This pressure caused an eruption under the fingerboard that cracked the fingerboard and lifted the 18th fret. To address this, I loosened the trussrod, glued and clamped the fingerboard down with a caul that was relieved over the fret so it pushed down on the fingerboard only. I sanded the fretboard some, then levelled the 18th fret to match the surrounding frets. This little bit of fretwork caused a ripple effect, and required me to polish all the other frets to produce a matching sheen.

It was like every little thing rippled into more work for this guitar. I've come to expect this from old guitars - and should always expect it from 12-strings - which is why I insist on having a complete trust-love triangle for a guitar of this age, a project this big. Super surprisingly, this guitar didn’t need a new saddle or nut.

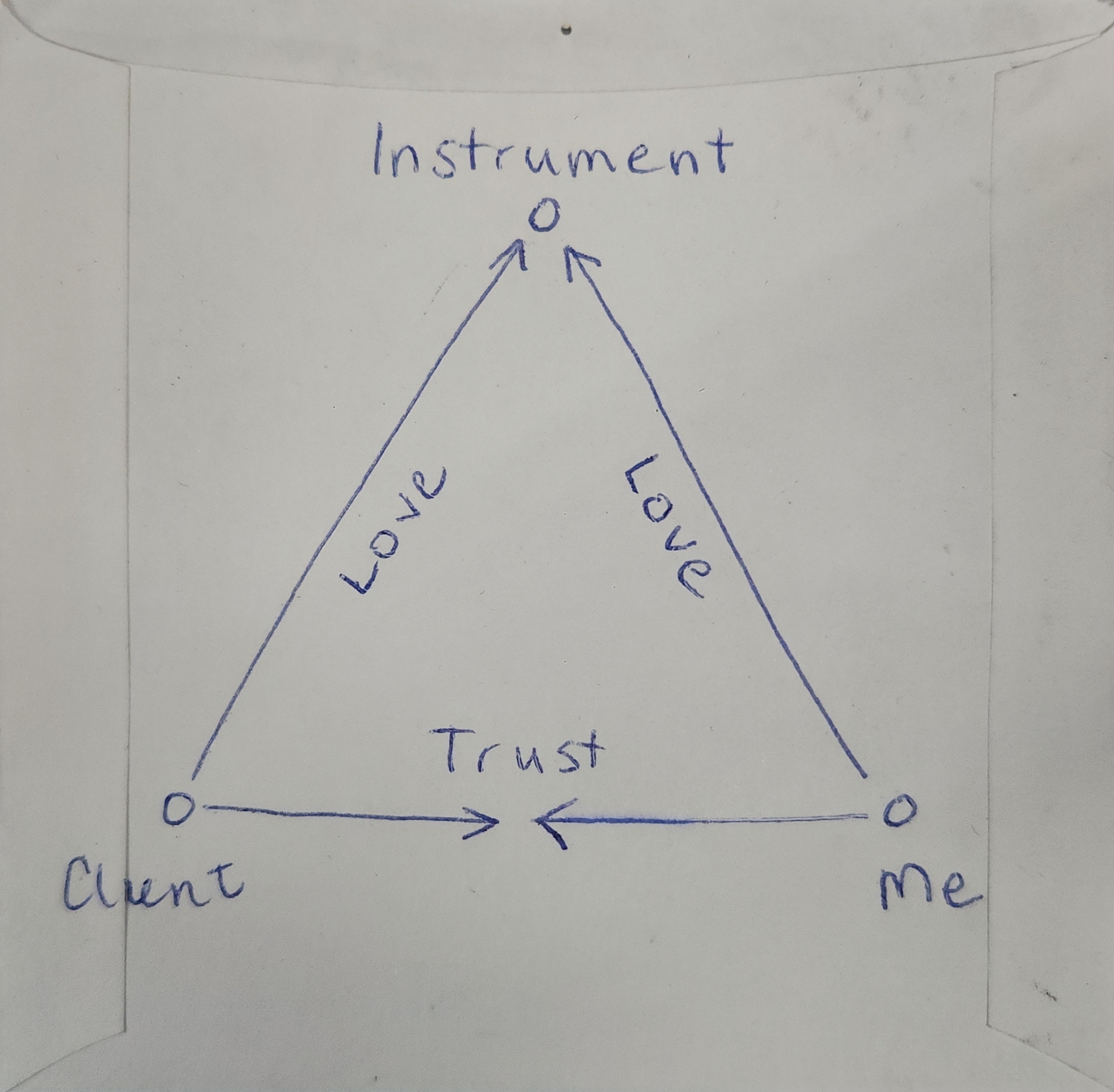

Do you remember my love-trust triangle? It's my theory that my best relationships in my job have a combination of love and trust. It's not good enough that I've got the skills to do the work. A complete love-trust triangle guarantees a really good feeling service transaction. I jotted it down on the back of a pack of strings (the most renewable resource in a guitar shop). Here it is:

Vertex 1- If you love your guitar, I love your guitar - regardless of value.

You and I need to have trust flowing both ways:

Vertex 2- You need to trust that I'm going to do a good job.

Vertex 3- I need to trust that you're going to believe in the process and be patient with me.

I had a complete love-trust triangle with this client. He was so amazing to trust me with his dear guitar. In fact, he's always shown tons of trust in my skills. I'd go above and beyond for him and clients like him any day! And look how happy he's been with this guitar (keep in mind, this report about the guitar is a year after service)!

These days I play it all the time -- it sounds amazing, plays like a dream and looks like the functional veteran that it is. So proud of you and your work!

I don't have the lowest prices, and I can't provide the fastest service. I'm even choosy about who I'll work with on big projects like this, but I promise you, when we're well matched, magic happens! I can't wait to meet you and your beloved guitars!

(Still patting myself on the back for sneaking in the word vertex into this article!)

June 2024